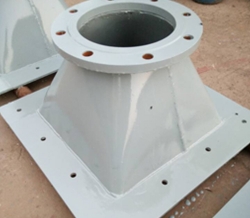

陶瓷紊(wen)流雙(shuang)套管(guan)(guan)是我(wo)公(gong)司(si)在(zai)紊(wen)流雙(shuang)套管(guan)(guan)基礎上做的進(jin)一(yi)步改進(jin),屬于國內首創,該(gai)產品由主(zhu)輸送(song)(song)管(guan)(guan)和固定(ding)在(zai)其內壁(bi)頂(ding)部的內旁(pang)通管(guan)(guan)組(zu)成,內旁(pang)通管(guan)(guan)上設有引流-阻尼隔(ge)板,底部沿軸向按工藝要(yao)求每(mei)隔(ge)一(yi)定(ding)間距(ju)設一(yi)開口,通過輸送(song)(song)管(guan)(guan)道的自(zi)調節實(shi)現飛灰的紊(wen)流狀(zhuang)態輸送(song)(song)。

陶瓷耐磨(mo)(mo)(mo)雙(shuang)套管(guan)從輸(shu)送(song)機理上有別于常(chang)規的正(zheng)壓(ya)氣力輸(shu)送(song)系統,改(gai)懸浮輸(shu)送(song)為靜壓(ya)輸(shu)送(song),從而改(gai)變(bian)了(le)常(chang)規正(zheng)壓(ya)輸(shu)送(song)低濃度、高(gao)流速、易磨(mo)(mo)(mo)損(sun)(sun)、易堵管(guan)的工況,是(shi)解決輸(shu)送(song)高(gao)磨(mo)(mo)(mo)損(sun)(sun)、大出力、密相輸(shu)送(song)磨(mo)(mo)(mo)損(sun)(sun)性大的物料(liao)(例如鍋爐(lu)飛灰)的理想方案,代表了(le)當今除(chu)灰技術的先進水平(ping)。

該(gai)裝置(zhi)包括主(zhu)(zhu)輸送(song)(song)(song)管(guan)(guan)、內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan),在(zai)(zai)主(zhu)(zhu)輸送(song)(song)(song)管(guan)(guan)的(de)(de)(de)(de)外(wai)(wai)壁(bi)上間隔設置(zhi)有(you)(you)多(duo)個焊(han)接(jie)孔,所(suo)述(shu)主(zhu)(zhu)輸送(song)(song)(song)管(guan)(guan)的(de)(de)(de)(de)外(wai)(wai)壁(bi)上沿(yan)軸(zhou)向方(fang)向刻(ke)有(you)(you)指引(yin)線(xian),并且焊(han)接(jie)孔位(wei)于指引(yin)線(xian)上。通(tong)(tong)過(guo)刻(ke)畫指引(yin)線(xian),在(zai)(zai)將內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)緊(jin)靠主(zhu)(zhu)輸送(song)(song)(song)管(guan)(guan)的(de)(de)(de)(de)內(nei)壁(bi)進行焊(han)接(jie)時,能(neng)夠(gou)(gou)(gou)保證足(zu)(zu)夠(gou)(gou)(gou)的(de)(de)(de)(de)有(you)(you)效焊(han)接(jie)部位(wei),使得內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)在(zai)(zai)受到高速灰氣流的(de)(de)(de)(de)沖刷時不(bu)易脫(tuo)落。在(zai)(zai)內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)的(de)(de)(de)(de)外(wai)(wai)壁(bi)上沿(yan)軸(zhou)向方(fang)向刻(ke)有(you)(you)定(ding)位(wei)線(xian),利用定(ding)位(wei)線(xian)能(neng)夠(gou)(gou)(gou)保證足(zu)(zu)夠(gou)(gou)(gou)的(de)(de)(de)(de)有(you)(you)效焊(han)接(jie)部位(wei)。在(zai)(zai)內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)的(de)(de)(de)(de)外(wai)(wai)壁(bi)上設置(zhi)有(you)(you)鉤掛裝置(zhi),能(neng)夠(gou)(gou)(gou)使內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)整體與(yu)主(zhu)(zhu)輸送(song)(song)(song)管(guan)(guan)的(de)(de)(de)(de)內(nei)壁(bi)接(jie)觸更加緊(jin)密。在(zai)(zai)內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)的(de)(de)(de)(de)入口處設置(zhi)防磨(mo)裝置(zhi),能(neng)夠(gou)(gou)(gou)延(yan)長內(nei)旁(pang)(pang)通(tong)(tong)管(guan)(guan)的(de)(de)(de)(de)使用壽命。適(shi)合(he)在(zai)(zai)物料輸送(song)(song)(song)領域推廣應用。

產品特性:

系(xi)(xi)(xi)(xi)統(tong)適應(ying)性(xing)(xing)強,可靠(kao)性(xing)(xing)高:耐磨陶(tao)瓷紊流雙套(tao)管系(xi)(xi)(xi)(xi)統(tong)獨特的(de)工(gong)作原理,保(bao)證了(le)除(chu)灰(hui)系(xi)(xi)(xi)(xi)統(tong)管道不易堵塞(sai),即使(shi)短時(shi)的(de)停運后(hou)再(zai)次啟動時(shi),也(ye)能迅速疏通,從而保(bao)證除(chu)灰(hui)系(xi)(xi)(xi)(xi)統(tong)的(de)安(an)全性(xing)(xing)和可靠(kao)性(xing)(xing)。這一(yi)特點也(ye)決定了(le)該系(xi)(xi)(xi)(xi)統(tong)對輸送(song)物料適用(yong)范(fan)圍更為(wei)廣泛,尤(you)其(qi)肘石灰(hui)粉(fen)、礬土等難(nan)以(yi)輸送(song)的(de)粉(fen)狀物料,比(bi)采用(yong)其(qi)他除(chu)灰(hui)系(xi)(xi)(xi)(xi)統(tong)更具擾勢;該除(chu)灰(hui)系(xi)(xi)(xi)(xi)統(tong)輸送(song)壓(ya)力(li)變化平緩,空壓(ya)機供氣量(liang)波動小(xiao),系(xi)(xi)(xi)(xi)統(tong)運行工(gong)況(kuang)比(bi)較穩(wen)定,從而改善(shan)了(le)除(chu)灰(hui)空壓(ya)機的(de)運行工(gong)況(kuang),延長設備(bei)使(shi)用(yong)壽命(ming),比(bi)常規的(de)單管氣力(li)除(chu)灰(hui)系(xi)(xi)(xi)(xi)統(tong)性(xing)(xing)能要(yao)好。